I think the Somaliland Gov’t should commission people like this fella who restore old machines for a hobby.

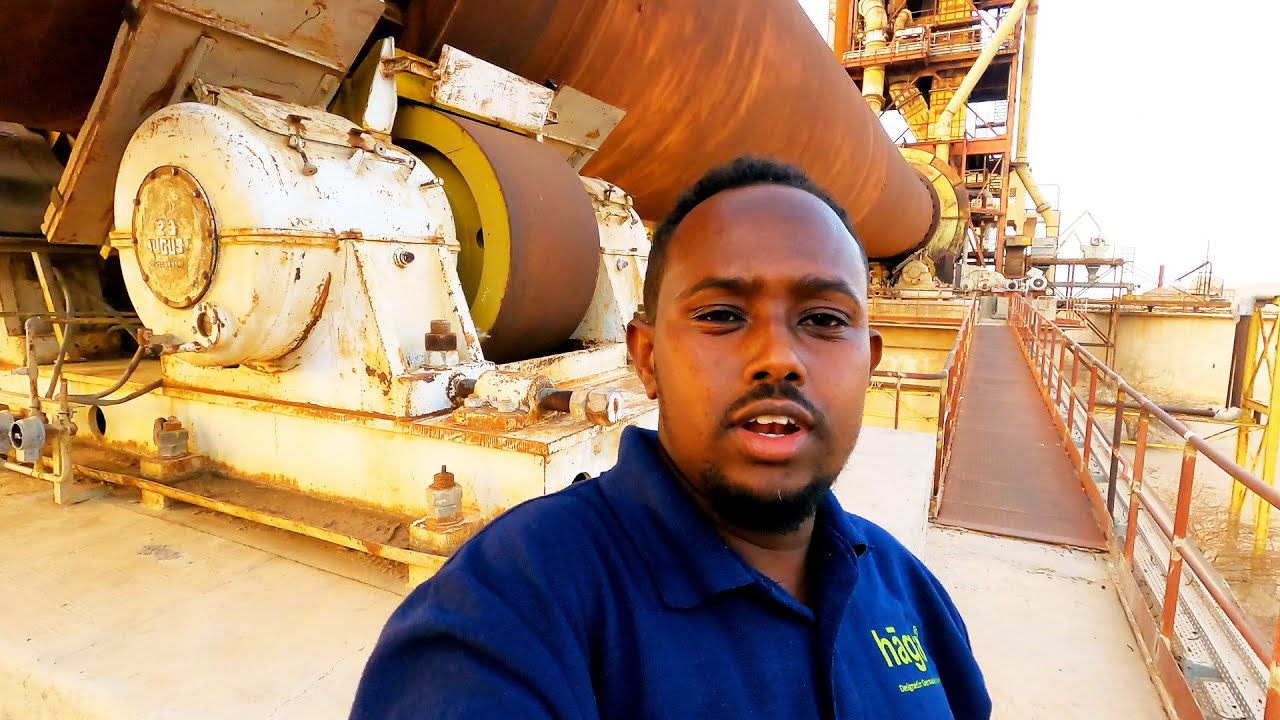

Berbera Cement factory has all the hardware intact only rusted. The only thing missing or broken is the electronics, which in these days, given the right technical knowhow resources, should be a piece of cake to design and recreate.

I think this Cement plant has a chance even with a minimum investment.

“Berbera’s defunct cement plant, built in the 1970s by French and North Korean companies”.

If this plant was built in the 1970s that would mean its based on designs/technology from prior to the 70s.

Granted, cement plants are probably basic in what they do in terms of crushing, grinding and heating but surely its more cost effective and environmentally friendly in the long run to start with a new / efficient modern plant.

https://www.facebook.com/Berbera-cement-factory-129965153846176/

PROJECT CONCLUSION & RECOMMENDATION

a) Conclusion: The study shows that the only possibility of the

plant to use its assets, most effectively, is to re-commission /

rehabilitate the same as is where is, at its present installed

capacity of 600TPD-Clinker / 700TPD-Cement. That would see

a logical and profitable beginning of the project once again after

lying untapped for 19 years.

Raw Material availability is in abundance for the plant to work for

coming 30 years. This includes Limestone, Gypsum and Clay. The

only imported component will be the fuel that the country anyway

imports for the power generation at national level. Therefore there is no

hindrance seen to the operations of the plant with respect to this

aspect of the project.

As regards manpower, it is envisaged that initially the plant will be

operated with Expatriate staff. This situation will change as with time

the skills will be developed locally. It will also be planned to send a

couple of qualified local personnel on some working plants for training.

b) Recommendation : We recommend, on the basis of this study,

to re-commission / rehabilitate the plant as it is and after

effectively operating same at its optimum potential, convert the

process to coal fired system from the present oil fired one in

order to achieve higher margins in working profits.

some highlights of the Berbera plant feasibility

The plant was initially planned on a wet process technology as the set up suggests. It

was however, changed and modified to a dry process system with installation of a

suspension pre-heater at the intermediate kiln length towards the feed-end after

sacrificing the first kiln pier towards the feed-end, thereby restricting the kiln length to 75

metres, finally. A redundant kiln pier and the slurry tanks are existing at site.

Existing Preheater is a four stage suspension type with a flash calciner incorporated.

This is used with a kiln of diameter 3.0m x 75m length. The combination suggests an

safe output of 600 MT of clinker a day, keeping in view the available Raw grinding

capacity. Raw mills are two in number each of capacity 22 MT max., thereby giving max.

44 MT of raw meal an hour, sufficient for production capacity of 600 tons of clinker a day.

Cooler attached to the kiln is a Grate type cooler of fuller -gatx make, again size suffient

for a capacity of 600 tons a day.

The main / major machinery on the site, that constitute Raw mills, Preheater, Rotary Kiln,

Grate Cooler, Cement mills, Silos, (Raw meal & cement both) material conveying

equipment, crushers, Packing plant and truck loading machines etc. are is a healthy

condition that can be put to operation with minor repairs and refurbishing.

Main Goals of the Project

In generally the project will primarily supply high quality cement to the local market which is currently have not cement production plants, By facilitating local cement production this project should strengthen Somaliland cement industry capacity, increasing the local value added while replacing the present high level of more expensive cement imports. The project is of particular significance being one of the first large scale private sector investments in the industrial sector in Somaliland, save the hard currency for Somaliland which goes abroad for buying Cement, subsidize its role in the economic growth and employment of the country, Provide new job opportunities to contribute in solving the unemployment problem in Somaliland in general.

http://www.tradearabia.com/news/CONS_387406.html

Raysut Cement’s new Duqm plant to be on stream by Q4

MUSCAT, 6 days ago

Raysut Cement Company (RCC), Oman’s largest cement manufacturer with a global footprint, said work is in full swing on its new $30 million grinding unit at Duqm and is on track to go on stream in the fourth quarter of 2021.

“Duqm plant will add another one million tonnes to our capacity, helping us cater to Oman and other regional markets with increased supplies, where construction activity is poised to pick up in post-pandemic resurgence,” said its Group CEO Joey Ghose.

The Duqm plant will raise RCC’s annual group output to 7.4 million tonnes, and help the Muscat Stock Market-listed company raise output to 10 million tonnes by 2022, he stated.

As part of developing the Duqm plant, RCC had signed a land lease and Port of Terminal services agreement with Port of Duqm Company. The new grinding unit will also complement RCC’s expansion and new investments and acquisitions in Oman, Asia and East Africa.

Last year, RCC had acquired Sohar Cement Company in Oman at $60 million. It is also developing a new greenfield 1.2 million tonnes per annum cement plant near Tbilisi, Georgia, at an investment of $200 million.

A majority takeover of LafargeHolcim’s cement terminal at Thilafushi Islands in Maldives and an investment of $40 million in a grinding unit in Berbera, Somaliland, are other RCC projects.

Chief of Support Services and Business Development Yousef Ahmed Alawi Alibrahim said the Duqm unit’s construction has been progressing despite the Covid-19 pandemic situation, thanks to the prudent safety and health protocols in place.

“This has been a challenging year for manufacturing industries in general, but RCC has been able to negotiate the hurdles with effective planning focusing on health and safety,” he noted.

The Duqm plant is also a milestone project for RCC to scale up its output to 22 million tonnes in the near future.-TradeArabia News Service

Why is it so hard to get clarity on this project.

Eng Ali, who is is an expert and senior staff of the Berbera Cement Factory and also the general Engineer of this factory during the late Somali Republic regime, has given detailed history, background and current status of the factory to the DG and the other officials.

The old factory is almost intact. Only needs electrical and new paint. The machinery needs some oil. That is all.

If they hire some of the restoration experts, I think they could bring this up and running with less than 5 million dollars invested.

In the meantime it would have made a good setting for a movie! Seriously though what quality buildings lasting this long, surprised they didnt use the buildings at least for municipal offices back in the day.

Red cement Factory is a group that unites 58 local companies, mostly those in the cement, energy, real estate, medicine , petroleum and construction industries.

From the Sool region to the Awdal region, the owners come from various parts of Somaliland.

Our primary goal is to restore the Berbera cement plant, which was severely damaged during the civil war in 1991.

Red sea cement Objectives

- To fulfill the needs of the country and demand of the local market in Somaliland

- To promote awareness of environment and community impacts of quarrying and business operations

- To achieve long-term social-economic development in Somaliland

- To utilize natural resources effectively and efficiently in Somaliland

- To create job opportunity for the local people in Somaliland

Cement Industry in Somaliland

Since 2000, demand for building materials in Somaliland was a growth driven by the expansion of the construction sector in the region when the government promoted large-scale infrastructure projects.

Reliable regional sources indicate that in 2019, cement use per person increased to 55 kg annually with the potential to reach 200 kg annually. Cement demand has increased over the preceding five years at a compound annual growth rate (CAGR) of 7 to 9%.

Today in Somaliland cement industry is becoming one of the potential major roots to promote employment opportunity and increase the tax revenue of the country. Moreover, the cement business can be the source of attracting foreign investors with the profitable opportunities in Somaliland .

Historical background of Berbera cement factory

his was a commercial joint venture between the Somali government and North Korea, the Koreans were supposed to bring the plant equipment and technical know -how. The Somalis were asked to pay for the transport, fuel, labor and everything that was not available in North Korea. As the Koreans were not capable of manufacturing cement equipment they in turn signed another agreement with Romania to manufacture the equipment for them. The Koreans decided to do the civil work only.

They asked the Romanians to make all the designs and manufacture the equipment and erect them (machines) when the North Korean accomplish the civil work. They promised to pay for the equipment, but when the Romanians manufactured the equipment the North Koreans could not find the hard currency to buy all the machines at one time and this because of stumbling block to the building of the plant.

The North Korea was bringing a number of machines every other two months and as a result the time dragged on and on. Time had no significance on their part while it was money on our side.

Any way the North Koreans were expelled after eight years and at that time only 60% of the civil work and 20% of the erection of machines was accomplished. a French firm called ( creosote Loire enterprises) took over the construction of the plant and the erection of the machines . They finished the job within two years (1983 – 1985). As cement was an industry alien to us another French firm called Lafarge (L .C .L LAFARGE COPPEA LAVALIN ) take over the training of the workers and the operation of the plant they trained 270 workers with in two years 1985 -1987 . At last the plant produced its first bag of cement in 17th of March1987. The plant was shut down on 23rd of June 1988 as result of the armed civil conflict which erupted in Burao and Hargeisa, and has been idle since then.

Over the past few years, the Project Sponsors have been carrying out investigation into the feasibility of establishing a cement factory in Berbera. The Project Sponsors have incorporated RSCC in Somaliland, which aims to construct a modern cement plant near the site of the old Berbera Cement Plant.

Red sea cement are initial Project Sponsors now they own the project on 100/100 basis. As per understanding with the Government of Somaliland, the Project Sponsors plan to open up the capital and invite both local and foreign investors to participate in the financing of the project.

The project sponsors have commissioned extensive project feasibility studies. A number of technical studies have been completed, including feasibility study, geological investigation (Raw Materials Quality & Reserves), geotechnical investigations (Preliminary & Detailed), topographical mapping and a hydraulic investigation (Water).

Project Value to the Somaliland people

The project will have tremendous development impact for the country, the government and consumers and the investments. The Project Sponsors are responding to the Government’s development strategy, which is supportive of private sector development, national industrial development.

Major expected project benefits include:

-

- Imports reduction –As import-substitution project, RSCC will reduce imports and save foreign exchange for the country.

- Contribution to the government’s objective to develop local natural resources — the project is expected to have a catalytic impact on the country’s fledgling mining sector.

- Employment generation–Red Sea Cement Factory will employ 300 personnel across management, administrative, skilled and non-skilled roles with further additional jobs in transport, logistics, shipping and other support services.

- Technology transfer – the project will provide important skills development and specialized training opportunities for nationals. RSCC will liaise and cooperate with the local and national education authorities to develop the plant personnel.

- Development of management and technical talent – RSCC will cooperate with the Somaliland Universities and Colleges to develop management, technical, non-technical programs for the Somaliland graduates.

- Promotion of local industries–RSCC will promote the development of a cluster of local industries within the cement industry ecosystem.

I like the idea of inviting the public to have stake in the company. This type of investment makes the whole country share the profits instead of profiting going to just few wealthy bigwigs.

With an average of price of cement at $90 (optimistic) per ton according to the video and production capacity at 2000 tons per day = $180,000 per day. 315 operating days = $56 million per year?

$90 per tonne makes a 25kg bag around $2 - $2.5 per bag. In the market a 25kg bag of Omani cement sells for $7 - $8 USD.

The major cost they will face is importing Coal. 1 Ton of coal at market price is around $250 - $300. If they can keep the expenses in check, they can make healthy profit and still sell it at 2 - 2.5 per bag.

Also, if they were really want to make further profits they could add Steam generators which will use the excess lost heat to boil water and generate electricity.